|

This article first appeared in 2006 as a two-part feature in

WETT Ink, the newsletter of Wood Energy Technology Transfer Inc. The Florida Bungalow SyndromeDealing with Uncontrollable Non-catsBy John Gulland The owners of the new EPA certified

non-catalytic stove say they can’t control the fire and you are called

in to diagnose the problem. It is a beautiful installation with the flue

pipe running straight up to the base of a factory-built chimney that is

routed up through the second story and the steeply-pitched roof. The

owners say that even when they turn the air control off, the stove

continues to fire too hard and they can’t get it to burn for more than

four hours. You check for leaks, but the door and glass gaskets and ash

pan seals are fine. So why is the stove over-firing? The problem is that the stove was specifically designed to burn clean when used on a hot day and when connected to a very short chimney. Call it the Florida Bungalow Syndrome. This is how it came about. The story begins over twenty years ago in the western United States. In the mid-1980s, the U.S. Environmental Protection Agency was under pressure from the courts to meet its obligations under the clean air act and it turned its sights on wood stoves. The Agency began to develop an emissions test procedure based on one created by the State of Oregon a couple of years earlier. The laboratory test involved a total system height of 4.6 metres (15 feet) from the floor the stove sits on to the top of the chimney.

Everyone was convinced at the time that wood smoke pollution was mainly caused by smouldering, so the test demanded that stoves be able to burn very slowly without making a lot of smoke. The emission rate for a stove as certified by EPA is based on the average of four burn rates: low (air control turned off), medium-low, medium-high, and high (air control fully open). The stove must burn the wood, meaning the fire does not go out, and it must not smoulder too much, even when the air control is turned as low as it will go, or the stove will fail the test. To meet the low-burn part of the test, the stove designer must build in a fixed minimum air supply opening. In other words, a sizeable combustion air leak. Because catalytic stoves can burn at a very low smoulder in the firebox and rely on the catalyst to clean up the smoke, they don’t tend to need minimum air inlets as large as non-cats do and therefore don’t tend to suffer as much from the Florida bungalow syndrome. Under the test conditions with a fifteen foot system height and a warm lab, at say 28°C (80°F), the chimney draft experienced by the stove would be at about the minimum possible. If we assume a high-burn temperature difference of 200°C (380°F) between the flue gases in the chimney and the air in the lab, we can calculate that the stove would experience about 25 pascals of draft or 0.1” water column. If all wood stove users had very short chimneys and only burned wood in warm summer weather, then stoves would behave in the real world much like they do in the lab. But few people who heat with wood live in bungalows in Florida. What happens when we take that EPA certified non-cat stove and connect it to a tall, straight venting system like the one you were called in to diagnose? We can calculate that at the same 200°C (380°F) temperature difference the draft on a 7 metre (23 ft) tall system would be 38 Pa, which is 52 percent higher than on a fifteen foot system, and on a 35 foot system the draft would be 59 Pa, or 136 percent higher. As we all know, the amount of draft produced by the chimney it is connected to makes an enormous difference in the way a wood stove functions. To bring that relationship into clearer focus, below is a table of calculated draft levels, depending on stack height and flue gas-to-outdoor temperature difference. Pressure differences resulting from various temperature differences

and various stack heights, in pascals

Notes: 1.

The

red figures in the body of the table are the number of pascals of

pressure difference that result from the intersecting temperature

difference and stack heights. One Pa is equal to 0.004"wc. 2.

The

lower two rows of the table body can be used to roughly estimate total

stack effect (- & + values) in houses during cold weather. 3.

A

single point flue gas temperature measurement, usually at the flue pipe,

will give a higher temperature than the average for the total system

because of heat loss through the chimney, and therefore will inflate

actual draft levels unless a correction is applied. 4.

Combustion

and venting system height measurements should be taken from the base of

the firebox; i.e. from where it gets hot. This raises an interesting question. If draft level is so important to stove behaviour – which everyone acknowledges – then why is it assumed that a stove that is ‘optimized’ for low draft conditions (with a fixed minimum air control leak) will work properly under high draft conditions? It would appear, judging from the absence of discussion and debate on the subject, that few if any people who worked on the development of EPA’s emissions regulation were aware of the relationship between temperature difference, system height and draft, and its consequences for stove operation. The first step in refining a standard after several years of use is to recognize that there are aspects that need correcting and the second step is to reach a consensus on changes that will solve the problem. In this case, however, a simple revision will not be possible. If the EPA emissions regulation had been developed under a consensus process the way CSA and UL/ULC standards are, it would probably have been modified by now to solve some of the many problems that have arisen. But EPA developed the ‘standard’ internally in a process of negotiation with various stakeholders. The result is that the EPA rules are frozen in time, 1988 specifically. All these years later the EPA has lost the staff expertise it once had in wood stove emissions testing, and probably the financial resources to initiate an amendment process. Not only that, but some wood stove manufacturers are concerned that opening a revision process would only lead to changes making the emissions test more difficult to pass. Since there is little chance that the test rules will be modified to address the Florida bungalow syndrome, the question becomes this: What can be done by the dealer, installer or sweep to help a customer who can’t get a reasonable burn time from their new appliance because it won’t turn down? Four different solutions have been suggested. Unfortunately, none of them is without drawbacks. They are:

Before we consider each of these options, it might be useful to frame the issue and look at the language used to describe it. The phrase “over-drafting” is often heard in discussions of problems like this, but it could be argued that there is no such thing. The phrase implies that the venting system is at fault for making too much draft. This may seem a little odd considering that one of the industry’s original and long-standing problems has been low draft caused by oversized, outside, uninsulated chimneys and long, convoluted flue pipe assemblies. To now say that a straight venting system installed inside the house makes too much draft could be seen as technically inconsistent with earlier efforts to convince people that exactly this type of venting system is preferable. The appliance design, not the venting system, is the source of the short burn times that cause dealer call-backs. Modern wood burning appliances are no longer called “airtight”, because they aren’t, but they are called controlled combustion to distinguish them from open or leaky decorative fireplaces and old cast iron box and parlour stoves.

The real problem is that some EPA certified non-cats don’t provide enough control over the firing rate because their manufacturers must optimize stove performance to pass the emissions tests, the conditions of which duplicate those of a Florida bungalow: that is, a very short chimney and very high outdoor temperature. Now, let’s review each of the four possible solutions. It has been suggested that a restrictor plate with an opening of perhaps four or five inches be installed under the chimney cap to reduce draft. Such a restrictor would work by reducing the flow capacity of the chimney, slowing the rate of flue gas flow and providing more residence time for the flue gases to give up their heat to the chimney structure, leading to a lower average flue gas temperature and lower draft. The restrictor might resolve appliance over-firing, but could create the more serious problem of smoke roll-out when the loading door is opened for refuelling. That is because when you open the stove door to load it, the flue gas flow rate doubles or more as room air rushes in and up the chimney. It is under these conditions that you need the flow capacity of a six inch chimney to fully vent the exhaust, especially with EPA non-cats which have restrictive firebox exits and need a lot of draft to prevent smoke roll-out. The restrictor plate solution is probably not a good one because it tampers with the chimney structure, which is a certified device and isn’t really the cause of the problem in the first place. Not to mention that it creates the likelihood of smoke spillage indoors because it reduces chimney venting capacity.

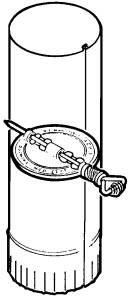

The third potential solution is to install a barometric draft control in the flue pipe. Although a barometric control could work, it would also vastly increase the amount of air consumed by the system. The higher the draft, the more the control swings open and the more room air would flow into the venting system. These effects would reach their maximum during the coldest weather when draft is highest. That would represent a considerable energy efficiency penalty and could create depressurization problems in a well-sealed new house. Also, the barometric control could be the easiest path for smoke spillage into the room in a house with negative pressure problems.

None of the optional solutions is without drawbacks. The result is that whatever option the dealer or installer chooses, he or she could be open to criticism. Here are a few recommendations that might help to resolve this problem over a period of time.

This is a complex issue that has not been widely discussed. As a result, I have expressed my own views here with the intention of igniting a dialogue on the subject. I look forward to hearing any comments you might have. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||