The effects of powered exhausts |

|||||||||||||||||||||||||||||||||||||||||

|

The pressure inside a building is affected when inside air is exhausted to outside. The amount of pressure change is influenced by:

Excessive depressurization of a house caused by exhaust flows can overcome chimney draft and result in venting failure. There are at least three housing trends that contribute to the increased frequency of house depressurization leading to venting failure. First, builders are giving more attention to air sealing of their houses for energy conservation and comfort reasons, so leakage rates are lower. Second, building materials are evolving; for example, standard doors and windows are more commonly gasketed and have effective latches that pull them tightly closed, also reducing leakage. And finally, modern clothes dryers and kitchen exhausts, usually the largest exhaust devices in a house, are more powerful than older models. In other words, houses are getting tighter and exhaust fans are getting more powerful. The result is more frequent and more severe depressurization of houses.

|

|||||||||||||||||||||||||||||||||||||||||

Intermittent exhaust devicesThe most common mechanical exhaust ventilators are the kitchen range exhaust, clothes dryer, central vacuum and bathroom fan. The operation of these devices, independently or in combination, causes house depressurization. None of these devices is designed to run continuously so they are referred to collectively as intermittent exhaust devices. Chimney vented hearths function as exhaust devices when they take air for combustion from the house and expel it outside. The exception would be those that get their combustion air from outside, but as we will see, outdoor air supplies have their own special problems. Because the air flow through open woodburning fireplaces (no doors) is uncontrolled, they can act as powerful exhausts, so powerful they have been sarcastically referred to by some housing specialists as wood-fired exhaust ventilators. In general, however, hearth appliances with doors, and particularly those with gasketed doors, draw comparatively little air from the house. Table 2 below shows the average air flows of common intermittent exhaust devices and combustion equipment. Table 2. Estimated air flows of typical intermittent exhaust devices

Average airflows of chimney vented combustion systems

*L/s is litres per second; cfm is cubic feet per minute. The figures in the table have been rounded off. Manufacturers of exhaust devices such as bathroom fans, kitchen range exhausts, clothes dryers and central vacuums generally publish higher air flow capacities than those shown in Table 2. This is because the manufacturer's ratings are performed under more ideal conditions than commonly occur in the field. Every additional elbow and length of duct contributes to the restrictions that reduce the net flow. Field tests have shown that actual flows are often about 40 per cent less than manufacturer's ratings. House depressurization chart

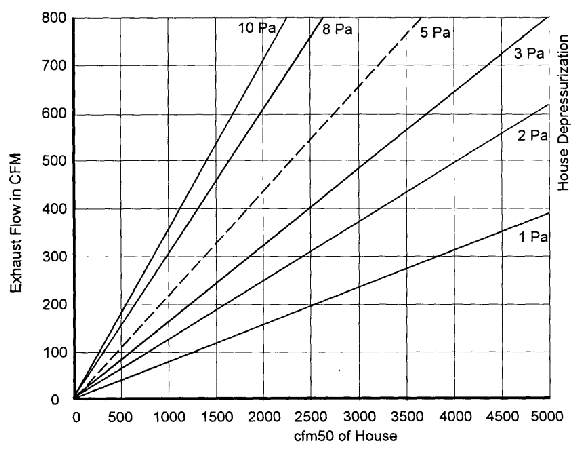

The chart above shows the effect of various exhaust flows on the pressure in buildings with envelopes of various degrees of leakiness. The figures on the vertical axis are the combined exhaust capacity of devices of concern, usually the clothes dryer and kitchen exhaust. The horizontal axis is the range of house leakiness expressed as cfm50 which is the number of cubic feet of air that would be exhausted each minute by a fan that depressurizes the building to 50 Pa. The diagonal lines show the resulting house depressurization at intersecting points of cfm50 and exhaust flow. The dotted diagonal line is the -5 Pa level at which the most sensitive chimney vented systems may begin to experience problems. According to the chart, a kitchen range fan that exhausts 300 cfm in a house with a leakage rate of 1500 cfm50 would depressurize the house between 4 and 5 Pa. To put the cfm50 figures into context, well built houses in northern United States and southern Canada would have leakage rates between 1000 and 1500 cfm50. A large house of complex design would have a higher leakage rate; a small house of simple design could be tighter. Houses built in milder climates where cold weather comfort and heating fuel economy are not high priorities will tend to have greater leakage. Old houses have far higher leakage rates than these. Looked at another way, a house with a leakage of 1500 cfm50 would have an equivalent leakage area (if the total of all leaks were expressed as the diameter of a hole) of roughly 16 inches. While the table is a useful tool for gaining insights into the relationships involved, the figures cannot be relied upon for predicting the behavior of a particular house. The house pressure test outlined later in this manual is the correct approach to predicting reliable venting.

Continuous exhaust devicesContinuous exhaust devices must be treated differently than intermittent devices because of the potentially greater impact they can have on hearth/chimney performance. The exhaust devices listed in Table 2 are all defined as intermittent in that they operate only for a period of time and then shut off. The only real example of a continuous exhaust device is an exhaust-only house ventilation system. Such ventilation systems can be as simple as a duct running from inside the house to an attic ventilator at the roof peak. Others use a fan exhausting through a wall or roof vent. More elaborate designs can have ducts connected so that stale, moist air is picked up from the kitchen and bathroom areas and forced out of the house with a fan. |

|||||||||||||||||||||||||||||||||||||||||

|

As house envelopes are built tighter to increase comfort and reduce energy consumption, a point is reached at which an active ventilation system is required to provide fresh air for healthy living and to remove pollutants and excess moisture from the house environment. The most obvious evidence of the need for ventilation in tight houses in cold weather is the condensation of water vapor on windows. Because the operation of continuous exhaust devices spans the start-up and tail-out periods during which a hearth is most vulnerable to house depressurization, they are more likely to cause venting failure than intermittent devices. In fact, they are almost certain to present problems, particularly when the appliance and chimney are in standby mode (no fire). Unfortunately, exhaust-only ventilation systems are becoming more popular because they are the least expensive way to ventilate tight houses. With exhaust-only ventilation systems, air to replace that which is exhausted is expected to enter through leaks in the building envelope, whether random leaks or planned leaks such as those built into window frames. The tighter the house, the greater is the level of depressurization needed to induce the required replacement air flow. Ventilation systemsIdeally, tight houses with natural draft hearths should have balanced ventilation systems, in which replacement air from outdoors is forced into the house in the same volume as the stale air is exhausted. The additional cost of balanced ventilation is relatively minor, but the benefits go beyond providing a safer environment for chimney venting, and include more effectiveness and comfort, and lower energy consumption for the homeowner. The most common form of balanced ventilation system is the heat recovery ventilator, or HRV, which has become popular in regions with cold winters. During cold weather the heat recovery feature of these units both saves energy and moderates the temperature of the in coming air so that it does not create discomfort. Balanced ventilation systems are available without heat recovery at lower cost than HRVs.

Inside a heat recovery ventilator (HRV), stale air from the house passes through a heat exchanger in close proximity to a stream of cold outdoor air, giving up some of its heat to the cold air and moderating its temperature. Successful chimney venting is assisted by balanced ventilation. In other words, the absence of balanced ventilation is an adverse house feature and its presence is a driving feature. This factor has important implications for architects, builders and hearth specialists. You can help to ensure successful venting through your recommendations to the homeowner.

A heat recovery ventilator must not be used to supply combustion air or to compensate for air exhausted by other appliances. In cold weather, if more air is brought into the house through the HRV than is exhausted, the moisture in the exhaust air will freeze in the heat exchanger core, blocking air flow. In order for the HRV to function properly, the fresh air and exhaust air flows must be balanced. The furnace fan as a room exhaustThe air distribution ductwork serving a forced-air furnace can be designed and installed in such a way as to cause zone depressurization in a building. This phenomenon is often linked to the enclosure of joist spaces in a basement to form part of the cold air return duct system. This common design feature, referred to as joist lining or panning, involves nailing sheet metal across joist spaces to form a duct, the sides of which are the joists, the bottom of which is the sheet metal and the top of which is the floor above. Installers rarely seal the space properly to prevent air leakage. When the furnace fan starts, the cold air return ductwork is put under negative pressure. Air flowing through leaks in the joist panned ducts has the effect of depressurizing the basement. In fact, with leaky return air ducts, an operating furnace fan effectively pumps air from the basement to the higher levels of the house. This imbalance of the duct system and resulting zone depressurization can cause venting problems for chimney vented combustion equipment in the basement. In this illustration, notice that the cold air return grilles are on one side of a partition wall, typically the kitchen, dining room, and living room area, yet there are five supply registers in the isolated section, which might be where bathroom and bedrooms are located. With the furnace fan running, the bedroom area would be pressurized and the main area, where a hearth would commonly be located, would be depressurized. Zone depressurization can also be caused by a lack of free air circulation between rooms. For example, if the installation of wall-to-wall carpeting reduces the gap under the doors to bedrooms and other rooms, the operation of the furnace fan can cause depressurization of the zone in which the cold air returns are located, typically the central area made up of living room, dining room and kitchen. In this case, the air forced into the rooms with doors closed cannot easily flow back to the cold air return registers, resulting in zone pressure differentials. This phenomenon appears most commonly in houses outfitted with central air conditioning systems which move a high volume of air.

Problems with the original system design can also cause imbalance. For example, systems designed with two or more zones controlled by thermostats in various locations of the house can cause zone depressurization because it is common to zone control only the supply side of the distribution system. Those areas of the house that are not being heated receive no supply air but return air is removed, potentially causing depressurization. Forced-air distribution systems should be balanced so their operation does not influence the pressure of any room in the house. Using the house pressure test outlined later in this manual, you can measure the effect of the furnace fan on room pressure. If the effect is significant, remedial measures should be recommended. In some cases it may be advisable to call in a central heating system contractor to conduct thorough testing and make the necessary alterations to resolve the problem of system imbalance. Such remedial measures can help to correct combustion venting problems. Summary

|

|||||||||||||||||||||||||||||||||||||||||