Building envelope basics

|

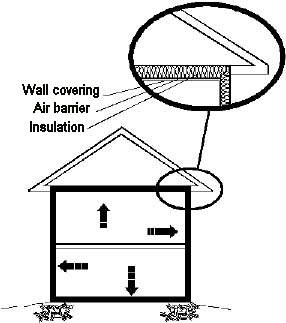

| The

envelope of a building encloses the living space, including the

basement, and isolates the interior of the building from the heat or

cold, and wind outside. Uninsulated attics or crawl spaces are not

considered to be within the building envelope. |

| In

normal wood frame construction, the envelope consists of the lumber

frame with insulation, usually fiberglass, placed between framing

members. The insulation is intended to reduce conductive heat loss or

gain through the envelope. An air barrier covers the frame and insulation

on the inside to reduce air leakage into and out of the envelope. The

air barrier in warm to moderate climate zones is often formed by the

wall covering such as drywall. In colder zones, a polyethelene sheet is

normally installed behind the wall covering to further reduce air

leakage. In tight home construction the joints in the air barrier are

caulked to seal them, as are all joints at windows and doors. All

penetrations of the air barrier, such as electrical outlets and

fixtures, are carefully sealed to the air barrier.

The

reduction of air leakage into or out of the building (infiltration and

exfiltration respectively) has three main purposes. The first is to

reduce energy costs for either heating or cooling. The second is to

improve comfort in winter by reducing cold drafts. And the third is to

prevent the migration of moisture-laden indoor air into the insulation

space, where in winter, the water vapor will condense and become

trapped in the insulation. This trapped moisture can damage the

insulation and lead to structural deterioration in attics by initiating

rot in wooden members.

|

The

building envelope is shown here and in the other illustrations in this

book as a thick, dark line, because its relationship with the hearth

and chimney system is important, as you will soon discover.

|

|

|

|

|

From

a building science perspective, it is preferable for the house pressure

to be neutral or slightly negative in order to reduce the forced

exfiltration of moist air into wall and ceiling insulation. The

practice of pressurizing the house, even though it might assist in

reliable chimney venting, is strongly discouraged by building

scientists. For this reason, the pressurization of houses is not

recommended here except in special circumstances and for short periods.

|

| All

building envelopes have leaks, but the range in the leakage rates of

the existing housing stock is very wide. Leakage rate of a building is

often expressed in terms of its equivalent leakage area or ELA which is

the size of hole you would get if all the leaks in a house could be

gathered together in one place. A large old house that has not been

weatherized might have an ELA equal to a hole three feet in diameter.

By comparison, the ELA of a modern house built with energy conservation

in mind might be equal to a hole only seven inches across. |

The ELA of a leakyold house can be equivalent to a hole 3 feet in diameter.

|

| A

large house will have a larger ELA than a smaller house built using

similar methods and materials because of its larger surface area. A

house with a complicated shape and features such as roof dormers is

likely to have a larger ELA than a simple, box-shaped house because it

is more difficult to seal. Therefore, small houses of simple design can

be "tight" without the builder or owner being aware of it. |

The ELA of a modern energy conserving house can be equivalent to a hole only 7 inches in diameter.

|

|

|

The

leakage rate of buildings is often expressed in terms of air changes

per hour (ACH) refers to the number of times in an hour that all of the

air in a building is replaced with outdoor air. In winter and in strong

winds old unweatherized houses can have leakage rates of up to 6 ACH.

Under the same weather conditions, a very tight house may have a

natural leakage rate far lower. Building scientists consider 0.35, or

about one-third ACH, to be the minimum ventilation rate necessary to

provide fresh air for healthy living and for the control of moisture

and odors.

|

|

Many

tightly-constructed new homes have a natural ACH rate that is below

0.35. The difference between the natural ACH in new houses and 0.35 ACH

creates the need for mechanical ventilation systems. Some of these

systems cause continuous house depressurization, which causes problems

for combustion systems vented by natural draft.

|

|

The

most obvious indicator of house tightness in winter is indoor humidity.

The water vapor produced by breathing, washing and cooking builds up to

high levels in a tight house with inadequate ventilation and reveals

itself as condensation of moisture on cold windows. Leaky houses, in

contrast, tend to have low humidity in winter because the moisture

created in the house is flushed out rapidly by the high infiltration

rate of the cold, dry outside air.

|

|

Builders

in mild climate zones give less attention to air sealing of houses

because heating costs are lower and leakage does not cause discomfort

to the inhabitants. However, sometimes houses are built tight by

accident when certain building materials are used. For example, if a

builder uses high-quality doors and windows with gaskets, and the

exterior is done in stucco or some other continuous surface, the house

could end up being fairly tight without anyone involved being aware of

it. If you live in a mild climate zone, you may encounter cases in

which the tightness of the building envelope is a factor in the failure

of a chimney vented system, but this usually happens because a large

exhaust device depressurizes the house. Later on you will learn that a

leaky envelope is no guarantee of successful chimney venting.

|

Summary

|

- building

envelopes are being constructed more tightly to increase comfort, to

reduce energy consumption and air exfiltration to structural components

- pressurizing buildings is not considered to be good building science

- there is a wide range in leakage rate among the existing housing stock

- the

natural leakage rate of tight houses may not be sufficient for healthy

living; mechanical ventilation systems are one solution

- condensation

of moisture on windows in winter is the most obvious sign that a house

is tight enough to need mechanical ventilation

|